For the home improvement and building materials industry, responding to the sustainable development strategy is to continuously introduce green and environmentally friendly materials and production processes. Among them, natural wood and stone resources are constantly declining, and over-exploitation can also lead to the destruction of the natural environment. The emergence of UV printers makes it very simple to make natural textures on other materials, and the printed results are natural and realistic, with rich texture.

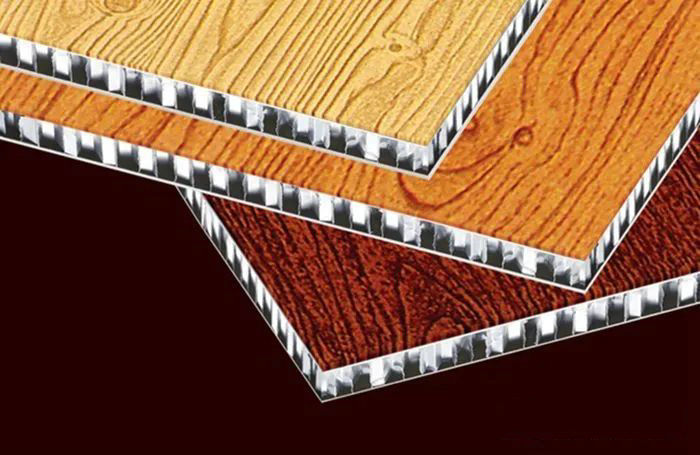

The introduction of environmentally-friendly building materials has been accelerating, such as artificial marble, PVC, bamboo fiber, honeycomb aluminum panels, etc., are constantly developing in the direction of lighter, more environmentally friendly and cheaper. In the past two years, honeycomb aluminum panels can be said to be a hot market, and various honeycomb aluminum panels that mimic natural textures such as wood grain and marble are more and more popular in the market. In the production process, the common ones are roller coating, wood grain film, solid wood leather, and the use of digital inkjet equipment such as UV printers that we will talk about next.

Roll coating, wood grain film, solid wood leather and other production processes are generally streamlined equipment, suitable for mass production, otherwise there is no economic benefit. For scenes with small and medium-sized batches and personalized patterns, UV flatbed printers highlight their own advantages. Only one device and one picture are needed to print surface textures. However, since the printing speed of conventional UV flatbed printers is generally tens of square meters per hour, for some large-volume manufacturers, such speeds cannot meet their production needs.

So, is the process of UV printing not suitable for mass production? actually not. In order to meet the demand for production capacity in industrial applications, UV printer manufacturers continue to invest a lot of research and development on the printing speed of the equipment. UV printing imitates natural texture building materials, which is environmentally friendly, and is not restricted by the supplier’s color and color, and has strong personalized attributes and is not subject to batch restrictions. In addition, the use of UV printers also has obvious advantages in terms of labor costs and processing costs.