During the printing process of flatbed printer, UV lamp will generate a certain amount of heat If the material to be printed is a material sensitive to temperature, it may bulge and the edge may rise, affecting the normal printing operation. Therefore, aluminum alloy vacuum adsorption platform came into being.

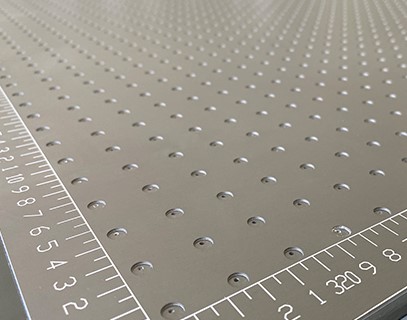

The vacuum adsorption platform is an aluminum honeycomb structure, which is made of aluminum alloy materials. The surface has extremely high flatness. In addition to the advantages of aluminum honeycomb plate such as light weight, high strength, large rigidity, bending resistance and bending resistance, it also has the advantages of high flatness, small deflection value, large adsorption force, scratch resistance and wear resistance. Detailed advantages are as follows:

1. Light weight and high bearing capacity

The vacuum adsorption platform is all made of aluminum materials, with aluminum honeycomb structure. It can bear 100 kg per square meter without deformation.

2. Customer customization

The vacuum adsorption platform is customized according to the needs of customers. Whether it is the platform specification, size, aperture and hole distance, suction area, suction aperture, number of suction ports, interface mode or any partition, it can be customized with or without suction, which may meet the requirements of customers.

3. Large suction and uniform suction

The optimized design of the vacuum adsorption platform can not only ensure that the performance of the platform is not affected, but also make the suction at any position of the platform large and average.

4. Scratch resistance, wear resistance and corrosion resistance

There are various treatment processes for the surface of the vacuum adsorption platform, including fluorocarbon, anodic oxidation and hard oxidation. The fluorocarbon process can be selected according to practical needs. The fluorocarbon process is scratch resistant, wear-resistant and corrosion resistant, and its surface hardness can reach hv500-700, which effectively prevents the corrosion of the prepress treatment materials on the platform.